Allan Huysamen, Business Development Manager – Adjuvants

Effective pest management with stomach-action insecticides does not only depend on the active ingredient, but also on how well it is ingested by the pest. This is why phagostimulants – the compounds that encourage feeding – are crucial in ensuring optimal uptake of the relevant thripicides.

While many products in the market position themselves as sugar-based feeding stimulants, not all are created equally. SUGAR RUSH™ is a premium formulation which maximises feeding stimulation activity through its carefully designed formulation and specific sugar composition.

Feeding stimulant activity of various sugars

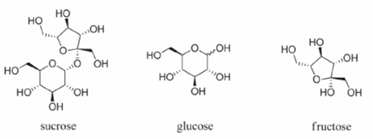

The chemical class of sugars consists of many different types of sugar molecules, simple or complex. Simple sugars, which are the type of sugars discussed in this article, include both monosaccharides (single sugar units) and disaccharides (two sugar units bonded together). Commonly known “refined white sugar” is a pure form of sucrose, a disaccharide sugar consisting of the monosaccharide sugars glucose and fructose, bonded together (Figure 1).

It is important to understand that not all sugars have the same effect on insect feeding stimulation. Some sugars result in a much greater insect response. Research has consistently shown that sucrose is one of the most potent feeding stimulants for plant-feeding insects, eliciting strong responses in their receptors that regulate feeding behaviour1,2.

Studies across a range of insect species have demonstrated that sucrose consistently triggers stronger and more reliable feeding responses than other sugars, highlighting sucrose as the most important sugar for stimulating ingestion. Glucose, for example, has been shown to be 30 – 50 % less effective than sucrose. The stimulatory effect of other naturally occurring sugars such as fructose at specific (lower) concentrations within these product formulations should however not be overlooked.

Figure 1: Chemical structures of sucrose (disaccharide) and its monosaccharide sugar components, glucose and fructose.

Sugar inversion process

Certain products that are positioned as sugar-based feeding stimulants in the market are prepared using inverted sugar syrups, which are produced through the breaking down of sucrose into glucose and fructose through heat and acid treatment. In the food industry, inverted sugar syrups are widely preferred over sucrose solutions due to their increased sweetness, lower viscosity (greater flowability), resistance to crystallisation and their moisture retention properties. Furthermore, as these syrups are often produced from unrefined sugarcane extract and supplied in bulk, it generally results in a cost reduction.

As a feeding stimulant for use in agriculture, inverted sugars present significant limitations. Firstly, their composition is dominated by glucose and fructose, both of which are less effective phagostimulants, therefore less suitable for enhancing the ingestion of stomach-action insecticides. Another potential risk relates to the interpretation of insecticide product labels that recommend the addition of sucrose for bait spray applications. If producers add inverted sugars to the mixture (which would be less effective), the recommendation is strictly and technically speaking not complied with, leaving producers potentially exposed when the efficacy of the product is challenged or questioned.

In sugar syrups, the “degree of inversion” refers to the degree to which the sucrose has been broken down. For example, a 75 % inverted syrup means that 75 % of the sucrose has been degraded into glucose and fructose. This translates into a 75 % decrease in concentration of the sugar which has the most potent insect feeding stimulant effect.

How to identify inverted sugar products

It is possible to distinguish between inverted sugar products and high-quality, sucrose-rich stimulants through several technical and practical indicators. Product SDS documents of inverted sugar products may indicate the degree of inversion of the sugar syrups, or may indicate glucose and fructose as major components. If such information is not provided on product SDS documents, inverted sugar products can be discerned by their lower viscosity, or increased “runniness”. Furthermore, inverted sugar products are often presented at a significantly lower price point in the market due to their bulk supply, less refined raw materials and less intensive production processes.

Why SUGAR RUSH™ is different

The SUGAR RUSH™ formulation is the result of intense research and developed specifically to maximise feeding stimulation of target insects through its high sucrose content and additional sugar components present at specific concentrations. The use of high-purity, refined sugars as raw materials differentiates SUGAR RUSH™ from products produced through inversion, ensuring consistency and reliability. Unlike inverted sugar products, SUGAR RUSH™ complies with insecticide label recommendations which specify sucrose for bait spray applications, giving producers confidence in both performance and compliance. In addition, the product is fully miscible and compatible with Agri Technovation foliar feeds and other relevant agricultural remedies, making it a versatile and effective tool for use in crop protection programmes.

Conclusion

Not all sugar-based products offer equal value when it comes to stimulating insect feeding. Products relying on inverted sugars with significantly lower sucrose content, may result in cost savings but through their use, efficacy, compliance and, ultimately, effective pest control are compromised. By contrast, SUGAR RUSH™ is a premium sucrose-rich solution, formulated with precision to ensure superior feeding stimulation, compliance and optimal return on investment.

References:

1. R. F. Chapman, Annu. Rev. Entomol., 2003, 48, 455-484.

2. E. Merivee, A. Must, E. Tooming, I. Williams, I, Sibul, Physiol. Entomol., 2012, 37, 369-378.