Plant-based protein hydrolysates: Biostimulants for the future

by Rochelle Thuynsma Head of Products: Technical, Agri Technovation

Introduction

Plant biostimulants include a wide range of products derived from natural and biological sources that offer a potentially novel approach to enhance crop growth and quality, nutrient uptake, and/or resistance to stress.(1,2,3) Recently, protein hydrolysates have gained a lot of attention as an emerging class of biostimulants that are beneficial for crop growth and production under a variety of stress-induced conditions.(1,2)

Amino acids: What are they and what do they do?

Amino acids are small molecules that combine in certain predetermined sequences into various chains (peptides) to form functional proteins. These protein chains then combine and fold into various configurations to produce functional components such as enzymes.

Amino acids are therefore one of the fundamental building blocks of life.(1,2) Amino acids are organic compounds that contain both amino and carboxylic acid functional groups. The differing functional groups present in any amino acid determine its chemical, physical, and functional characteristics.(4,5) Functional characteristics are also affected by the configuration of the functional group in relation to the central carbon atom. Amino acids are referred to as having either an L (laevus) or D (dextro) configuration.(4) This is important as bacteria and fungi are known to use D-amino acids exclusively, while plants and animals largely utilise L-amino acids for metabolic function.(5)

What are peptides?

Peptides can be defined as short chains of amino acids. These amino acids are connected to one another in a sequence by peptide bonds. When compared to proteins, peptides are distinguished by their shorter length with chains of two or more amino acids.(4,5) On the other hand, proteins, sometimes referred to as polypeptides, are lengthy molecules made up of several peptide components. Proteins can be broken into short peptide fragments by enzymes which carry out biological tasks within cells.(4,5) For instance, several peptides function as hormones, which when released from cells, affect various regions in the plant. To date, many different types of peptides have been discovered, each with its own distinct role.(1,2,4)

Figure 1: Amino acid and peptide structure of proteins.

How are protein hydrolysates manufactured?

Protein hydrolysis refers to the process during which a protein’s peptide bonds are disrupted, and free amino acid residues are released.

Several processes exist to produce protein hydrolysates such as chemical, thermal, or enzymatic hydrolysis.(4,5)

Chemical hydrolysis

This process includes an alkaline or acid hydrolysis process, resulting in a high free amino acid content. During acid hydrolysis (low pH) a strong acid is used, during which peptides are completely hydrolysed and amino acids like tryptophan can be destroyed.(5) Alkaline hydrolysis occurs at a high pH and can chemically cause the reduction of various amino acids to form unusual amino acid residues.(5)

Both these processes may also cause racemisation, where L-amino acids are changed to D-amino acids. Racemisation is one of the main contributors to the phytotoxicity of animal-based protein hydrolysates when applied to crop plants.(5)

Thermal hydrolysis

During this process, high-temperature liquid water is used to break down proteins into smaller peptides and soluble substances. Thermal hydrolysis can speed up the breakdown of large-molecule proteins in organic materials while limiting nutrition loss and protein denaturation to a minimal degree.(5) Loss of functional peptides is, however, high, as most proteins will denature at temperatures above 60 ⁰C. This method produces high levels of free amino acids but tends to have fewer stable peptides.(5)

Enzyme hydrolysis

The hydrolysis of proteins can also be achieved with the use of enzymes that break down proteins, called proteases. Proteases are specialised enzymes that break down proteins at either internal amino acid sites (endo-proteases) or amino acid sites present at the ends of peptides (exo-proteases).(4) They can be used as a single enzyme, a mix of enzymes or applied in sequential treatment steps.

Enzymatic hydrolysis can be performed under very mild conditions and avoids the extreme environments required by chemical or thermal processes.(4) Since this breakdown is facilitated by an enzyme, the optimal condition for extraction is determined by the optimal conditions the enzyme requires to function.

Enzyme-assisted protein hydrolysis avoids detrimental side reactions and racemisation, retaining the biostimulant and nutritional value of the original protein source. Another advantage of using enzymes is their highly selective function ensuring the resulting product composition and quality to be much more consistent.(4)

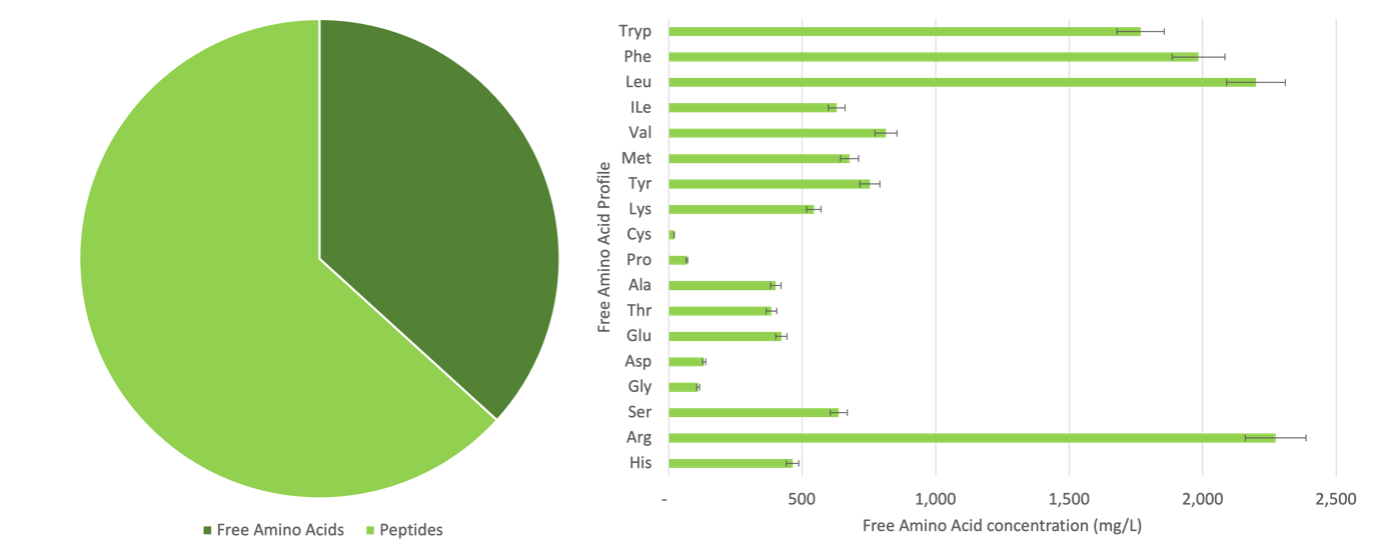

Figure 2: Composition of a Plant based protein hydrolysate as determined by LC-MS/MS analysis, p <= 0,05.

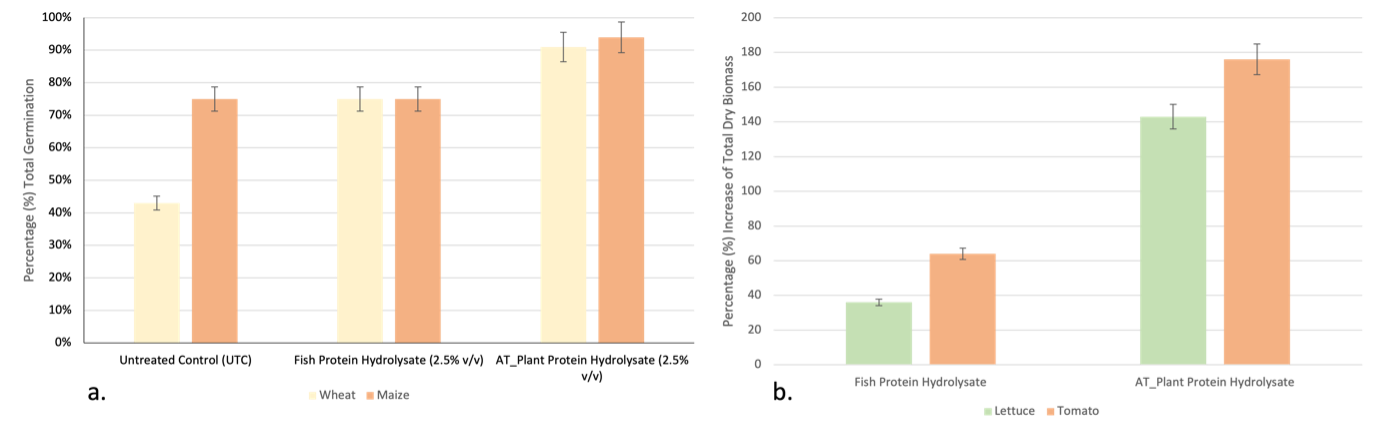

Figure 3: Effects of an AT plant-based protein hydrolysate (when compared to conventional fish-based hydrolysates on (a) germination of wheat and maize, or (b) growth of lettuce and tomato plants, p <= 0,05.

Why plant-based protein hydrolysates?

Protein hydrolysate’s final activity is based on the source material as well as the hydrolysis process used to produce the final product. The type of response elicited from the plant is however also dependent on the source of the protein.

Animal protein hydrolysates have been used in agriculture for more than 50 years utilising mainly chemical and thermal production processes.( 4,5) Animal protein hydrolysates generally contain an unbalanced amino acid content (animals do not synthesise all amino acids and need to acquire some of them through their diet) and low peptide content. Although used to enhance plant metabolism and resistance to environmental stress conditions, they appear beneficial and efficient only when applied at very low rates.(5,6) Care should however be taken as frequent or excessive applications can lead to hazardous and negative effects on crops.

On the other hand, plant-based protein hydrolysates are being recognised as a superior replacement for animal-based protein hydrolysates. They can be produced via enzymatic hydrolysis of plant biomass and consist mainly of a mixture of amino acids (all 20 essential amino acids that plants synthesise de novo), and short-chain bioactive peptides.(6,7) These amino acids and peptides are highly plantavailable and recognisable, due to their similar origin. Moreover, no phytotoxicity symptoms have been reported using plant protein hydrolysates, even at rates much higher than those recommended by manufacturers.

Agri Technovation’s plant-based protein hydrolysate

Through intensive research and development over a number of years, Agri Technovation has produced its own range of enzyme-assisted plant-based protein hydrolysates.

The benefit of the change is evident in the physiological plant response we see when incorporating these extracts into our products as well as their use as pure protein extracts. The flexibility of enzyme-assisted protein hydrolysis opens the door for specific targeted approaches to producing extracts for specific physiological responses or crop-specific reactions. It also allows for the use of various source materials, facilitating the expansion of this process to further develop other specialised plantbased hydrolysates.

Producing the plant-based protein hydrolysate

Agri Technovation’s (AT) plant-based protein hydrolysates have been extensively trialed and characterised to ensure consistent quality. The proprietary process involves a number of different specialised enzymes and the overall processing scheme and process variables have been optimised on bench, pilot and commercial scales. This process produces extracts containing both free amino acids and bioactive peptides as identified by mass spectrometry analysis, showing a rich blend of amino acids including high levels of arginine, tryptophan, phenylalanine, and leucine (Figure 2; Table 1).

Efficacy testing of the plant-based protein hydrolysate

A high bioactivity has been observed by evaluating the benefits of crop germination and biomass production in response to the application of plant-based hydrolysates.

Germination of seeds was monitored daily for 7 days, where total cumulative germination was higher with the application of our plant-based hydrolysate when compared to conventional fish-based protein hydrolysate (Figure 3a).

Seedlings also showed favourable results when the plant-based protein hydrolysate was formulated into AT foliar products. Lettuce and tomato seedlings accumulated more dry biomass when compared to seedlings receiving an AT foliar product formulated with fish-based amino acids (Figure 3b).

Conclusion

Plant-based protein hydrolysates are gaining more popularity as plant biostimulants due to their high levels of bioactivity, low risk of phytotoxicity, improved plant response, renewability as well as sustainability. They are complex mixes of free amino acids, with small and large peptides playing a large role in the final activity of the extract.

Agri Technovation’s plant-based protein hydrolysates are highly effective in stimulating plant growth as well as aiding in germination when compared to traditional fish-based hydrolysates. The source of protein, extraction, as well as processing conditions, all ensure consistent quality of the extracts produced, while formulating the plant-based protein hydrolysates into our existing products further enhances their performance and quality.

References:

- Hubbarao, SB., Aftab Hussain, IS., Ganesh, PT. 2015. Bio Stimulant Activity of Protein Hydrolysate: Influence on Plant Growth and Yield. J Plant Sci Res. 2015;2(2): 125.

- Colla, G., Hoagland, L., Ruzzi, M., Cardarelli, M., Bonini, P., Canaguier, R., Rouphael, Y. 2017. Biostimulant Action of Protein Hydrolysates: Unravelling Their Effects on Plant Physiology and Microbiome. Frontiers in Plant Science 8.

- Malécange, M., Sergheraert, R., Teulat, B., Mounier, E., Lothier, J., Sakr, S. 2023. Biostimulant Properties of Protein Hydrolysates: Recent Advances and Future Challenges. International Journal of Molecular Sciences 24(11):9714.

- Czelej, M., Garbacz, K., Czernecki, T., Wawrzykowski, J., Waśko, A. 2022. Protein Hydrolysates Derived from Animals and Plants-A Review of Production Methods and Antioxidant Activity. Foods 11(13):1953.

- Olantoni, A., Recchia, L., Bernabei, G., Cardarelli, M., Rouphael, Y., Colla, G. 2017. Analyzing the Environmental Impact of Chemically-Produced Protein Hydrolysate from Leather Waste vs. Enzymatically-Produced Protein Hydrolysate from Legume Grains. Agriculture 7.

- Colla, G. 2014. Biostimulant Action of a Plant-Derived Protein Hydrolysate Produced through Enzymatic Hydrolysis. Frontiers in Plant Science, 2014.

- Colla, G., Cardarelli, M., Bonini, P., Rouphael, Y. 2017. Foliar Applications of Protein Hydrolysate, Plant and Seaweed Extracts Increase Yield but Differentially Modulate Fruit Quality of Greenhouse Tomato. HortScience 52(9): 1214.

- Colla, Giuseppe, et al. 2015. Protein Hydrolysates as Biostimulants in Horticulture. Scientia Horticulturae 196: 28.